Last updated on January 9th, 2024 at 02:29 pm

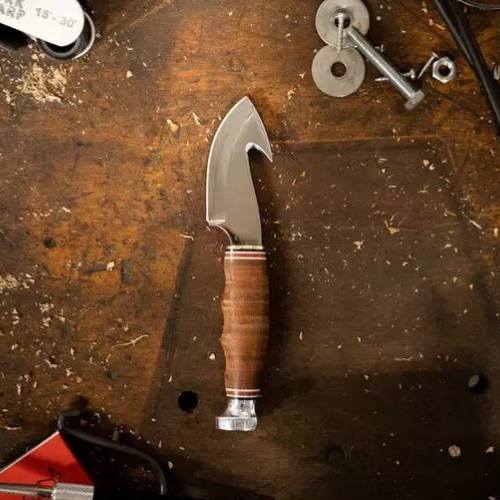

Cutting and Carving require the correct instrument. Every carpenter needs a hook knife blade. This blade shape has many advantages that make it ideal for any job. This post will describe hook knife blade benefits, how to choose one, and how to use it.

What is a Hook Knife Blade?

Hook knife blades are curled inward to give a hook shape. High-quality steel blades might have a curvature on the inside or exterior. Some models have plastic or metal handles, but most are wood.

Woodworkers utilize hook knife blades for spoons, bowls, and other curved things. They can also carve relief sculptures, chairs, and elaborate wood designs.

Advantages of Using a Hook Knife Blade

Hook knife blades have several benefits:

Versatility – hook knives are versatile. The curving blade can carve spoons and sculpt complicated motifs. Hook knife blades are great for woodworkers of all levels.

Precision – hook knife blades are precise. The curved blade lets you create precise cuts and curves that would be impossible with a straight blade. Carving complicated motifs or curving things requires this precision.

Efficiency – hook knives are also more efficient. The curved blade removes more material per pass, saving time and effort.

Comfort- finally, hook knife blades are easier to use. The blade’s curved design makes it easy to grip and reduces hand strain.

Types of Hook Knife Blades

Each hook knife blade has its own advantages. Common types are:

Inward-curved blade – Hook knives usually have inward-curved blades. For spoons, bowls, and other curved objects, the blade curves inward towards the handle.

Outward-Curved Blade – Inward-curved blades are more common. For carving relief sculptures and delicate motifs, the blade curves outward from the grip.

Double-Edged Blade – Double-edged blades may cut in both directions due to their curves. This blade is ideal for spoons and other curving carvings.

Long-Handled Blade – its have longer handles than blades. This blade is designed for wood chopping and thick vegetation cutting.

Choosing the Right Hook Knife Blade

Considerations when choosing a hook knife blade include:

Blade Material – blade material comes first. Hook knife blades are usually composed of stainless or carbon steel. If neglected, carbon steel blades can rust. Carbon steel blades maintain an edge better than stainless steel blades, although they corrode more.

Blade Size – Another consideration is blade size. Hook knife blades range in size from small blades for carving spoons to big blades for carving furniture.

Blade Curve – it is also essential. The blade curvature can be inside or outside and vary in angle. Choose a blade curve based on your work.

Handle Material – it is last. Hook knife blades have wooden or plastic handles. Wooden handles are easier to grip and manage than plastic or metal handles, although they may break.

How to Use a Hook Knife Blade Effectively

A hook knife blade takes practice and technique. Starting tips:

Hold the Knife Properly – Grip the knife handle with your dominant hand. To support and manage the blade, place your other hand on top near the handle.

Use Your Body Weight – Apply body weight to the blade when cutting. Lean forward and press down to help the blade cut.

Follow Blade Curve – Follow the hook knife blade curve during carving. Make lengthy, clean cuts following the blade curvature with a sweeping stroke.

Rotate Material – Rotate the material you’re carving to stay comfortable and follow the blade’s curvature.

Use a Strop to Sharpen the Blade – A strop sharpens hook knife blades. A strop is used to sharpen the blade.

Common Mistakes to Avoid When Using a Hook Knife Blade

When using a hook knife blade, there are several common mistakes to avoid, including:

Applying Too Much Pressure – Too much pressure on the blade can dig into the material and make uneven cuts. Let the blade work with a light touch.

Not Following the Curve of the Blade – Cutting unevenly and inconsistently might arise from not following the blade curvature. For optimal results, follow the blade curve slowly.

Dull Blade – Dull blades make carving harder and produce jagged slices. Keep your blade sharp.

Maintaining Your Hook Knife Blade

Tips for hook knife blade maintenance:

Keep the Blade Clean – Clean the blade with a gentle towel after use. Mild soap and water can clean the blade.

Dry the Blade – To avoid corrosion, dry the blade after cleaning.

Oil the Blade – After cleaning and drying, lightly oil the blade to prevent corrosion and keep it oiled. If you’re cooking with a knife, use mineral or coconut oil.

Store the Knife Properly – To avoid rust, keep your hook knife blade dry and cool. Use a sheath or blade guard to prevent cuts.

Conclusion

Hook knife blades are versatile carving tools. Hook knife blades can assist woodworkers of all levels achieve their goals. By picking the perfect blade, operating it well, and maintaining it, you can get the most out of your hook knife blade and carve it for years.

FAQs

1. What is a hook knife blade used for?

Hook knife blades carve and shape wood and other materials.

2. How do I choose the right hook knife blade?

Choose a hook knife blade based on material, size, curve, and handle.

3. How do I use a hook knife blade effectively?

Hold the knife properly, utilize your body weight, follow the blade curve, twist the material, and sharpen with a strop.

4. What are some common mistakes to avoid when using a hook knife blade?

Avoid overusing pressure, not following the blade curve, and using a dull blade.

5. How do I maintain my hook knife blade?

To avoid rust and corrosion, clean, dry, oil, and store the blade after use.