Woodworking requires safety. Safety is important for woodworkers of all levels. The riving knife is a crucial woodworking safety element. This page discusses riving knives, their uses, and how they improve woodworking safety.

What is Riving Knife?

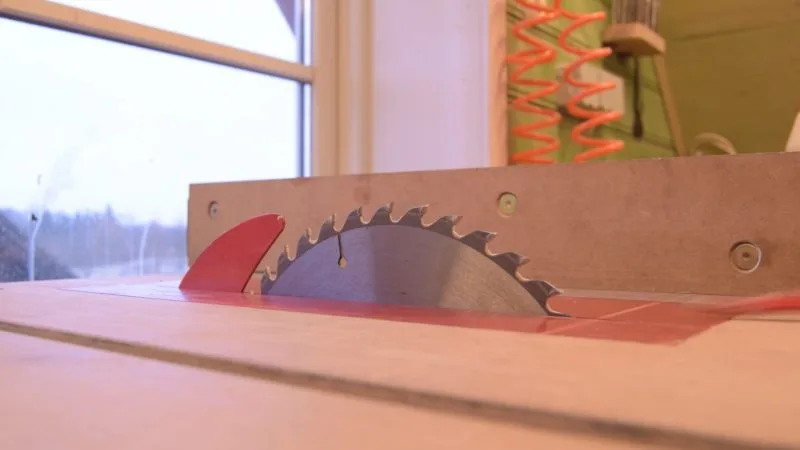

Table saw riving knives decrease kickback and enhance cutting precision. A thin, flat metal plate behind the saw blade aligns with the cutting path. A riving knife prevents wood from squeezing the blade, which can cause deadly kickback.

Importance of Using a Riving Knife

Ripping knives are essential for several reasons. Let’s examine its woodworking safety advantages:

Avoiding Kickback

Woodworking often involves dangerous kickback. When the wood piece gets caught between the blade and the fence, it is hurled back at the operator at tremendous speed. A riving knife reduces kickback. The knife keeps the cut kerf open, preventing backlash.

Sharpening Cuts

Besides safety, riving knives improve cutting precision. The knife just beneath the blade reduces wood vibration and aligns the workpiece during cutting. High-quality woodworking requires this alignment for cleaner, more accurate cuts.

Woodworking Operations Compatibility

Riving knives can handle a variety of woodworking tasks. A riving knife can be adjusted for rip cuts, crosscuts, and bevel cuts. Its versatility makes it essential for all woodworkers.

How Does a Riving Knife Work?

Especially in table saws, riving knives decrease backlash and improve safety. A metal or plastic plate is placed exactly behind the saw blade, aligned with the cutting edge.

A riving knife prevents the workpiece from binding or getting trapped on the blade, which can force the material toward the operator.

Using a riving knife:

Preventing kickback: Kickback occurs when the workpiece becomes squeezed between the blade and the fence, propelling it toward the operator. A riving knife prevents the blade’s kerf from closing. It prevents binding and backlash by separating the two cut workpiece portions.

Maintaining alignment: A riving knife keeps the workpiece aligned with the blade as it cuts. It prevents the stock from twisting or spinning during cutting, which can cause erroneous cuts or unsafe circumstances.

Clearing debris: Riving knives also remove sawdust, chips, and other debris from the cutting area. The knife’s small shape lets it slide through the kerf without blocking the material being cut while providing safety.

Adjustability: Modern table saws allow the riving knife to be modified in height and lateral position for varied cuts and blade settings. This flexibility keeps the knife aligned with the blade and prevents kickback.

Common Questions

Woodworking kickback: why?

Woodworking kickback can cause catastrophic injury. The operator may be injured by the fast-moving wood piece. A riving knife decreases kickback danger.

Are table saw riving knives compatible?

Riving knives vary by table saw model. They take blade size, arbor diameter, and mounting mechanism into account for each saw model. Use only the manufacturer-recommended riving knife for your table saw.

Can I use a dado blade without a riving knife?

Dado blades should not have the riving knife removed. The riving knife supports and protects all cuts, including dado cuts. It prevents backlash and promotes accurate, safe cutting. Use your table saw’s handbook for dado blade riving knife instructions.

Riving knife alternatives?

Riving knives are safe, but there are alternatives. Splitters work like riving knives on some table saws. Splitters are usually non-adjustable. They still guard against kickback.

Can I build riving knife?

Unless you have the skills and materials, making a riving knife is not recommended. Riving knives must meet table saw compatibility, thickness, and dimensions. An ill-fitting DIY riving knife might jeopardize safety and precision.

A riving knife for an older table saw?

Many older table saws can be retrofitted with riving knives. The saw’s design and retrofit possibilities determine this. Some older versions may need riving knife kits or adjustments. Talk to the manufacturer or a woodworker about retrofitting your table saw.

Conclusion

Finally, the riving knife prevents kickback and improves cutting precision in woodworking. By preventing the wood piece from binding on the blade, accidents and injuries are greatly reduced.

To make table saw operations safer and more fun, all woodworkers should use riving knives.

Woodworking safety should always be the main priority, therefore investing in safety tools like the riving knife is a good start.